By Barbara Gerke and Jan van der Valk

As part of our project, we ethnographically documented a case study of Sowa Rigpa medicine making (sman sbyor) techniques that reveals ideas of potency (nus pa) in practice. This involved apprenticing with a medical practitioner in Ladakh to process calcite or chongzhi (cong zhi). We chose the example of calcite rock, of which many types exit, because they can undergo a “hot,” “cold” or “wild” form of processing. This directs their potency to either increase the digestive heat (me drod) of the patient, or to having cooling properties that help calm stomach acidity.

Processed calcite powder is used both as an ingredient and as a pill coating in certain medical formulas. However, skillfully working with chongzhi is not just about finishing a pill, it is also “a phase in the life-story” of a substance—in our case a piece of rock that “grows” in remote mountain areas from where it is collected by amchi. We documented, for instance, how it was transformed during the full moon of the eighth Tibetan month into “moon ray calcite” (cong zhi zla ’od). This specific processing is said to enhance its cooling potency.

We are inspired by anthropologist Tim Ingold and historian of science Pamela Smith, who have shown that historical divisions and definitions of “making” and “growing,” “organisms” and “artefacts” in various societies are not as preordained as they seem at first glance. As stated in Ingold and Hallam’s edited volume titled Making and Growing, the maker or artisan “effects an ontological transformation in the material, not through the application of exterior force to inert substance, but through intervening in a play of forces and relations both internal and external to the things under production” (p. 4).

Many types of chongzhi are mentioned in Tibetan medical literature. They reveal the importance amchi give to the different environments from where they source their substances, as well as the importance of sensorial qualities and local lineage instructions.

Moon-ray chongzhi processing

We visited Amchi Tsültrim’s clinic in Leh in September 2018. He is a Gelukpa monk from Nubra and was trained at the Men-Tsee-Khang, graduating in the third batch of 1973. In September 2018, during full moon, Amchi Tsültrim allowed us to process calcite with him, which is made only once a year, during the most auspicious full moon of the eighth month in the Tibetan calendar, which typically falls into late August or September, when the moon is considered the brightest.

Amchi Tsültrim said it is the easiest to process. Crushing and grinding pearls, turquoise or lapis lazuli is a lot more difficult. Properties of materials are not merely ideas; they are real properties that amchi work with. We first spent hours crushing chongzhi rocks into small pieces by hand.

Then we boil twenty kilos of crushed chongzhi rocks several times in water on a gas stove in a large aluminum pot. Amchi Tsültrim changes the water after each round of boiling, until after four rounds, the water looks clear.

This process of boiling (cong zhi dug ’don) only removes the duk (dug) which is not poison in this context, but “what we don’t want”: dirt, other minerals, impurities of all kinds. Through this boiling, the chongzhi becomes clean, tsangma (gtsang ma) Amchi Tsültrim said: “We don’t use unclean materials in medicine, this makes the medicine rough and difficult to digest.”

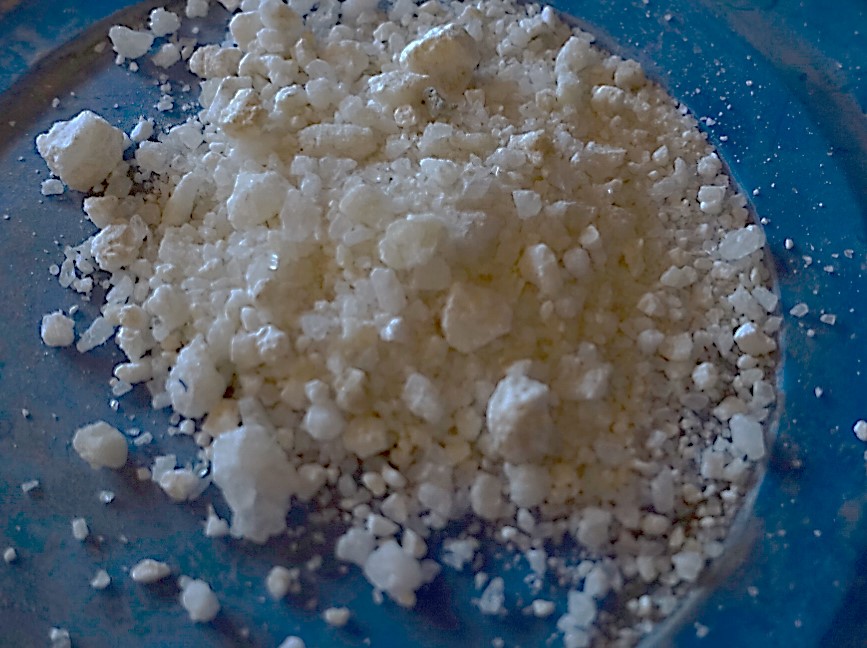

Five days later we were back, for another two days of grinding. This time the boiled chongzhi rocks had to be ground into fine white powder.

On the day of the full moon, Amchi Tsültrim had organized six liters of fresh dzomo (yak-cow hybrid) milk, which had been boiled. He started mixing some of the white chongzhi powder with six liters of dzomo milk in a large metal bowl. Amchi Tsültrim explained that the coolness we felt was a combination of the mixture’s exposure to the cold night air, and to moon light, which “is always cold.” Indeed, the aim of our kneading was primarily to expose every particle of the mixture thoroughly to the moonlight, while reciting the Medicine Buddha mantra.

It was around 11:30pm when we stopped the kneading and prepared sheets of washed plastic to place the round chongzhi cakes on that we formed by hand in uneven ways.

Making chongzhi daö with Amchi Tsültrim showed us that only by doing and making we could get a sense of the intricacies of the amchi’s skills, dexterity, and empirical knowledge, as well as practical necessities, limitations, and their dynamic interactions with the substances.